EpoxAcast™ 655

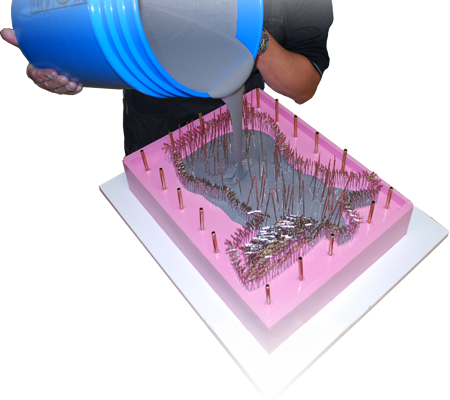

EpoxAcast 655 is an aluminum filled casting epoxy that is dimensionally stable even when mass cast. It is thermally conductive and fully machinable when cured. Choose Fast, Medium or Slow catalyst to fit your project. You can also use HT Hardener to give your castings higher heat resistance. EpoxAcast 655 is used for making vacuum forming dies, injection molds, foundry patterns and tooling fixtures.

-

▶

EpoxAcast™ 655 + 101Aluminum filled casting epoxy. Pot life of 30 minutes and cure time of 3 hours. Base and Hardener sold separately.WARNING: Prop 65

EpoxAcast™ 655 + 101Aluminum filled casting epoxy. Pot life of 30 minutes and cure time of 3 hours. Base and Hardener sold separately.WARNING: Prop 65 -

▶

EpoxAcast™ 655 + 102Aluminum filled casting epoxy. Pot life of 75 minutes and cure time of 9 hours. Base and Hardener sold separately.WARNING: Prop 65

EpoxAcast™ 655 + 102Aluminum filled casting epoxy. Pot life of 75 minutes and cure time of 9 hours. Base and Hardener sold separately.WARNING: Prop 65 -

▶

EpoxAcast™ 655 + 103Aluminum filled casting epoxy. Pot life of 3.5 hours and cure time of 24 hours. Base and Hardener sold separately.WARNING: Prop 65

EpoxAcast™ 655 + 103Aluminum filled casting epoxy. Pot life of 3.5 hours and cure time of 24 hours. Base and Hardener sold separately.WARNING: Prop 65 -

▶

EpoxAcast™ 655 + HTAluminum filled casting epoxy. Pot life of 4 hours and cure time of 24 hours followed by heat cure. Base and Hardener sold separately.WARNING: Prop 65

EpoxAcast™ 655 + HTAluminum filled casting epoxy. Pot life of 4 hours and cure time of 24 hours followed by heat cure. Base and Hardener sold separately.WARNING: Prop 65

Quick Tech Specs

EpoxAcast™ 655 + 101

- Mix Ratio By Weight 100A:10B

- Pot Life 30 minutes

- Cure Time 3 hours

- Shore Hardness 90 D

- Color Grey

EpoxAcast™ 655 + 102

- Mix Ratio By Weight 100A:11B

- Pot Life 75 minutes

- Cure Time 9 hours

- Shore Hardness 90 D

- Color Grey

EpoxAcast™ 655 + 103

- Mix Ratio By Weight 100A:12B

- Pot Life 3.5 hours

- Cure Time 24 hours

- Shore Hardness 90 D

- Color Grey

EpoxAcast™ 655 + HT

- Mix Ratio By Weight 100A:8B

- Pot Life 4 hours

-

Cure Time

Twenty Four Hours Followed By Post Cures

- Shore Hardness 90 D

- Color Grey

Videos

How-to videos can educate and improve your mold making skills.