Mold Max 14NV & 29NV

Shore 14A or 29A tin-catalyzed silicone which are low viscosity and do not require vacuum degassing.

Model makers throughout the United States know that Reynolds carries silicone rubbers and liquid plastics as the perfect combination to reproduce their creations and drive production.

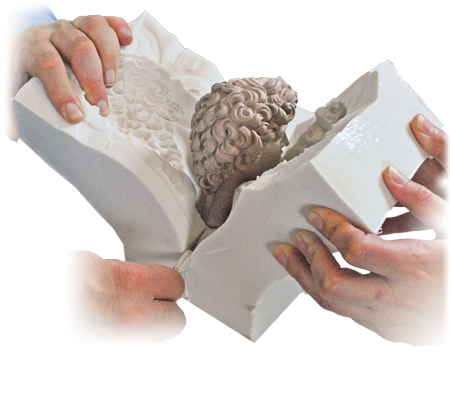

Smooth-On’s Mold Max Silicones have become the industry standard for making molds that capture very fine detail down to a fingerprint. With several to choose from, the Mold Max line covers most mold making scenarios and offers the model maker tremendous versatility. These materials are also used by firearms manufacturers, holster makers, law enforcement agencies, gun stock fabricators, museums, grip manufacturers, and more.

Smooth-Cast plastics and TASK plastics are then used to cast into these molds to make exact reproductions. SO Strong color tints and a variety of fillers can be added to create infinite effects. Cured plastics are also easily painted, giving the user complete creative control over the modeling outcome.

Shore 14A or 29A tin-catalyzed silicone which are low viscosity and do not require vacuum degassing.

Ultra low viscosity, 1:1 mix ratio white liquid casting resins.

Ultra low viscosity, 1:1 mix ratio off-white liquid casting resins.

Colormatch™ resins developed specifically for the addition of colorants.

Low viscosity, high performance white casting resins.

Polyurethane casting resin that is very strong when cast in ultra-thin sections.

High performance tin-catalyzed liquid silicone rubbers in Shore Hardnesses from 10A to 40A.