Mold Max 60

Heat Resistant Silicone

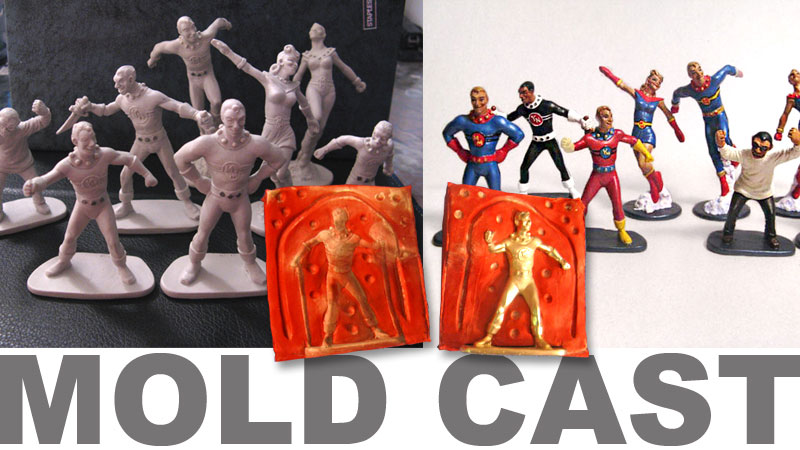

Mold Max® 60 is a Shore 60A tin catalyzed silicone rubber formulated for applications requiring high heat resistance (up to 560°F/294°C). It features a low mixed viscosity and cured rubber exhibits very low linear shrinkage. Applications include making foundry patterns, flat pattern reproductions and casting low-melt metal alloys such as tin and pewter. Cure time can be reduced with Accel-T® cure accelerator.

PLEASE NOTE: THI-VEX® Silicone Thickener is NOT recommended for use with Mold Max® 60.

Price and Purchasing

Call to Order

![[Return to Homepage]](/assets/imgs/RAMlogo.png)